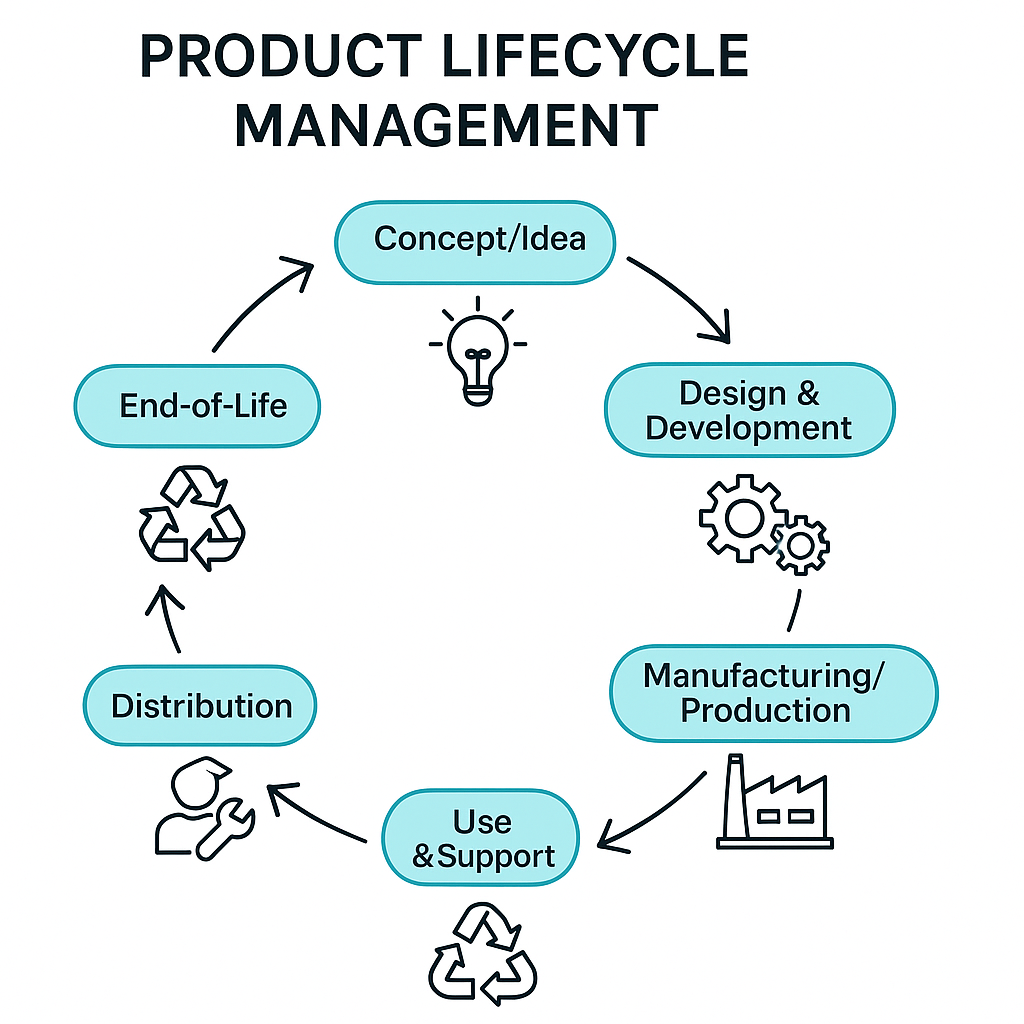

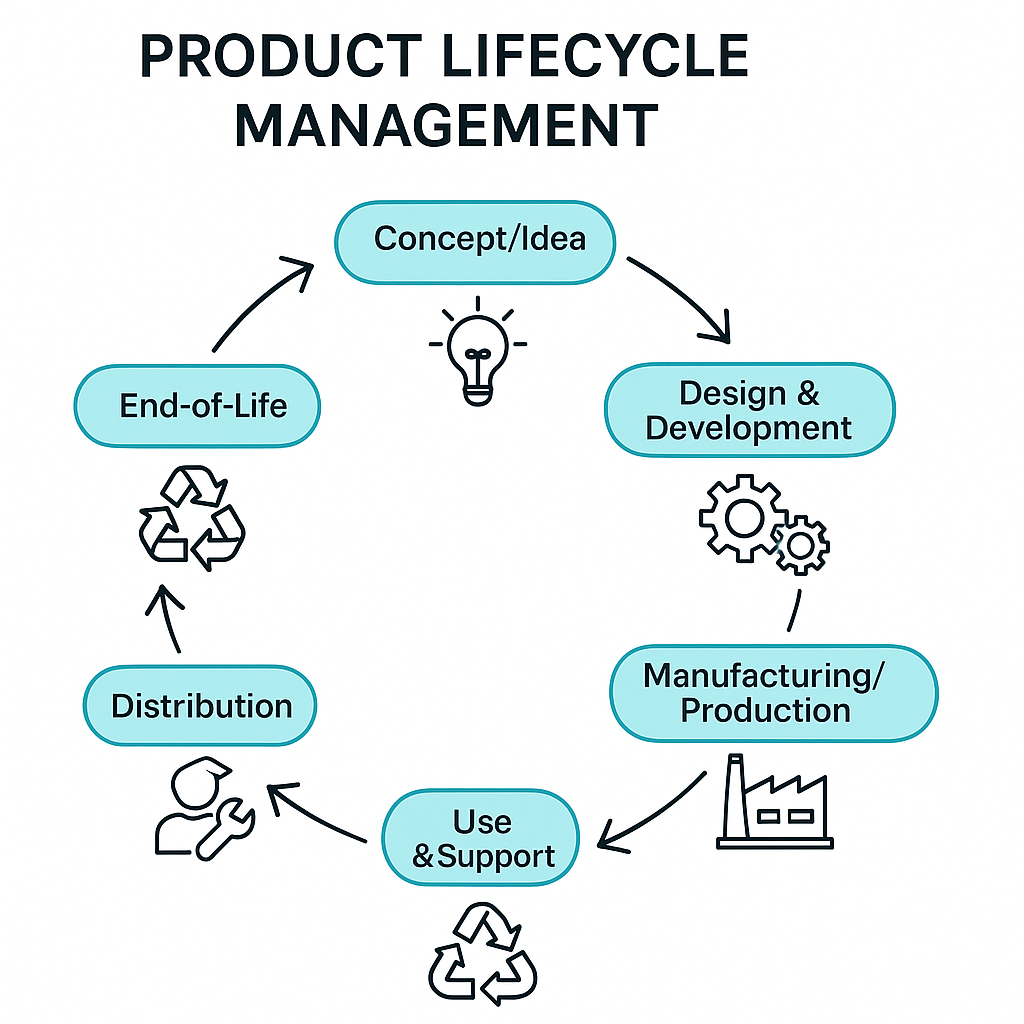

In industries where precision, efficiency, and speed are critical, PLM (Product Lifecycle Management) is the core solution driving product development from start to finish. From the first concept to the final product reaching consumers, this process ensures delivery of high-quality, innovative products consistently and efficiently. Let’s explore how product development management is reshaping the way businesses manage product lifecycles and driving innovation across industries.

What is PLM?

PLM is the practice of managing the entire lifecycle of a product, from its initial design and development to its final distribution and beyond. By centralizing all product-related data and workflows, it makes easier for teams to access accurate information, collaborate effectively, and drive projects forward without unnecessary delays or miscommunication.

At its core, product life cycle management software ensures that all stakeholders, from design to production, are working with the most up-to-date and relevant information.

How Managing Product’s Lifecycle Solves Industry Challenges

Every industry faces unique challenges in product development. PLM addresses these pain points by improving efficiency, ensuring product quality, and reducing time to market.

Breaking Down Silos and Improving Collaboration

One of the most significant challenges businesses face is fragmented communication. Teams often work in silos, making it difficult to ensure that everyone is on the same page. In this scenario, the top PLM software acts as a centralized platform that facilitates real-time collaboration across all departments involved in product development.

With product lifecycle management software, companies can:

- Centralize all product data, including design specifications, materials, and production timelines.

- Streamline communication by allowing real-time updates and instant sharing of information.

- Reduce errors caused by outdated or conflicting information.

By breaking down these silos, this technology creates a more cohesive, strong product development process that brings efficiency and minimizes costly mistakes.

Ensuring Consistent Product Quality

Maintaining consistent product quality is a top priority, but quality issues can arise at any stage in the lifecycle—whether during design, production, or post-production. Without proper oversight, these issues can become costly. The outcome will be customer dissatisfaction, and damage to a brand’s reputation.

PLM helps eliminate this risk by offering tools to monitor and manage quality across the entire product lifecycle.

With this software, businesses can:

- Track materials and components to ensure they meet required standards.

- Automate quality checks and revisions to minimize human error.

- Maintain a clear audit trail of design and production changes for easy traceability.

This level of oversight ensures that we uphold quality at every stage, minimize the risk of defects, and assure that the final product meets customer expectations.

Accelerating Time to Market

In industries where speed is mandatory, delays in product development can be a cause of missed opportunities and lost revenue. Here, this strategic process helps companies bring products to market faster by streamlining the design, prototyping, and production processes.

With product lifecycle management tools, teams can:

- Easily track project timelines and adjust schedules as needed.

- Create digital prototypes and iterate on designs without physical prototypes, reducing development time.

- Ensure smoother transitions between product lifecycle stages by aligning design, production, and sourcing teams.

By reducing unnecessary delays and bottlenecks, plm system gives businesses the competitive edge they need to stay ahead in the market.

Cost Efficiency Through Product Value Management

For many businesses, one of the key pain points is managing costs. PLM can help reduce operational costs, minimize waste, and improve resource allocation. This makes it a valuable tool for businesses focused on optimizing their bottom line.

Optimizing Resources and Materials

In product development, managing materials and resources efficiently is crucial. Over-ordering materials or failing to align production with actual demand can be problematic in case of excess inventory, increased storage costs, and wasted materials.

With plm tools, companies can:

- Track material usage in real time to ensure efficient allocation.

- Use historical data to forecast future demand and avoid over-ordering.

- Optimize material usage to reduce waste.

These capabilities lead to significant cost savings, making it an essential tool for companies looking to streamline operations and increase profitability.

Reducing Redundancies and Errors

When product teams work with outdated or incomplete data, errors and redundancies are inevitable. These mistakes can lead to costly reworks, delays, and project mismanagement. Product development management eliminates this risk by centralizing and streamlining product data, ensuring that everyone involved has access to the latest information.

By using this management software, businesses can:

- Avoid costly errors caused by miscommunication and outdated data.

- Reduce the number of revisions and rework required during product development.

- Save time and money by eliminating unnecessary steps.

By minimizing errors and redundancies, this innovative system enables businesses to work more efficiently, reducing costs and speeding up development.

Supporting Sustainability in Product Development

As consumers become more environmentally conscious, businesses must find different ways to reduce their environmental impact and create products that align with sustainable practices. Product value management plays a crucial role in enabling businesses to track and manage sustainability efforts throughout the product lifecycle.

Tracking Sustainability Efforts

From material sourcing to product disposal, PLM allows companies to track the environmental footprint of their products at every stage of their lifecycle.

With the updated process, businesses can:

- Monitor and reduce waste during production.

- Choose sustainable materials and suppliers.

- Improve recycling efforts by tracking end-of-life products.

Staying Competitive with Product Value Management Tools

Companies must be adaptable and quick to respond to changing customer preferences. These productive tools empower businesses to remain agile and competitive, offering the insights and capabilities necessary to respond to market shifts.

Leveraging Data to Drive Continuous Improvement

Continuous improvement is key to staying competitive. These systems provide businesses with valuable insights that help refine their products and processes.

Companies can:

- Analyze past product performance to identify areas for improvement.

- Respond quickly to changing consumer demands based on real-time data.

- Use historical data to predict trends and make data-driven decisions.

By making informed decisions based on actionable data, businesses can improve their products and remain ahead of the competition.

Adapting to Changing Consumer Demands

Consumer preferences can shift rapidly, and businesses must adapt quickly. Product life cycle managing offers the flexibility and real-time data necessary to make quick adjustments to designs, production schedules, and product offerings.

With product lifecycle management solutions, organizations can:

- Pivot designs and production plans based on market feedback.

- Personalize products to cater to specific consumer needs.

- Align production with current demand to avoid excess inventory.

For any company seeking to enhance its revenue, adopting a product lifecycle management system is a necessary step toward long-term success.

PLM is the major force behind product innovation and efficiency. By improving collaboration, ensuring product quality, reducing time to market, and promoting sustainability, it helps businesses overcome the biggest challenges they face in product development.