The fashion industry is rapidly evolving, with technology playing a key role in shaping its future. One of the most exciting developments in apparel manufacturing is 3D Garment Design. Brands like Nike, Adidas, and Zara are already using this innovative technology to change how clothes are designed and produced.

In this blog, we’ll explore the ways 3D clothing design is transforming the apparel manufacturing process and why it’s a game-changer for designers and manufacturers alike.

What is 3D Garment Design and Why Does it Matter?

The 3d software for garments designing allows designers to create digital, three-dimensional models of clothing. It allows them to see how garments will fit, move, and look before making physical samples.

Key points:

- 3D Clothing Design Software lets professional test and tweak their ideas virtually.

- Brands like Adidas use it to visualize designs quickly without wasting fabric.

- It helps catch fit issues and design flaws early, saving time and money.

With this software for designing clothes, the experts don’t need to rely on physical samples to evaluate their ideas. This leads to quicker decision-making and more efficient production, helping brands stay competitive in a rapidly changing market.

Let’s take a look at how 3D Garment Design increases efficiency in the apparel manufacturing process.

How 3D Clothing Design Programs Improves Efficiency in Apparel Manufacturing

One of the standout advantages of designing the clothes digitally is how it speeds up the design and production process. Traditional garment creation can take weeks, involving multiple rounds of samples and revisions. With 3d fashion design software, the stylists can quickly bring their concepts to life and make necessary changes in real-time.

Here’s how it works:

- Designers create a 3D model of the garment.

- They can quickly make adjustments to fit, style, and materials.

- The need for physical prototypes is minimized, saving time and reducing costs.

For example, Zara uses 3D Garment Design to bring their collections to market faster. This allows them to keep their offerings fresh and relevant while cutting down on production time and material waste.

Next, we’ll explore how this apparel design technology ensures that clothes fit just right on you.

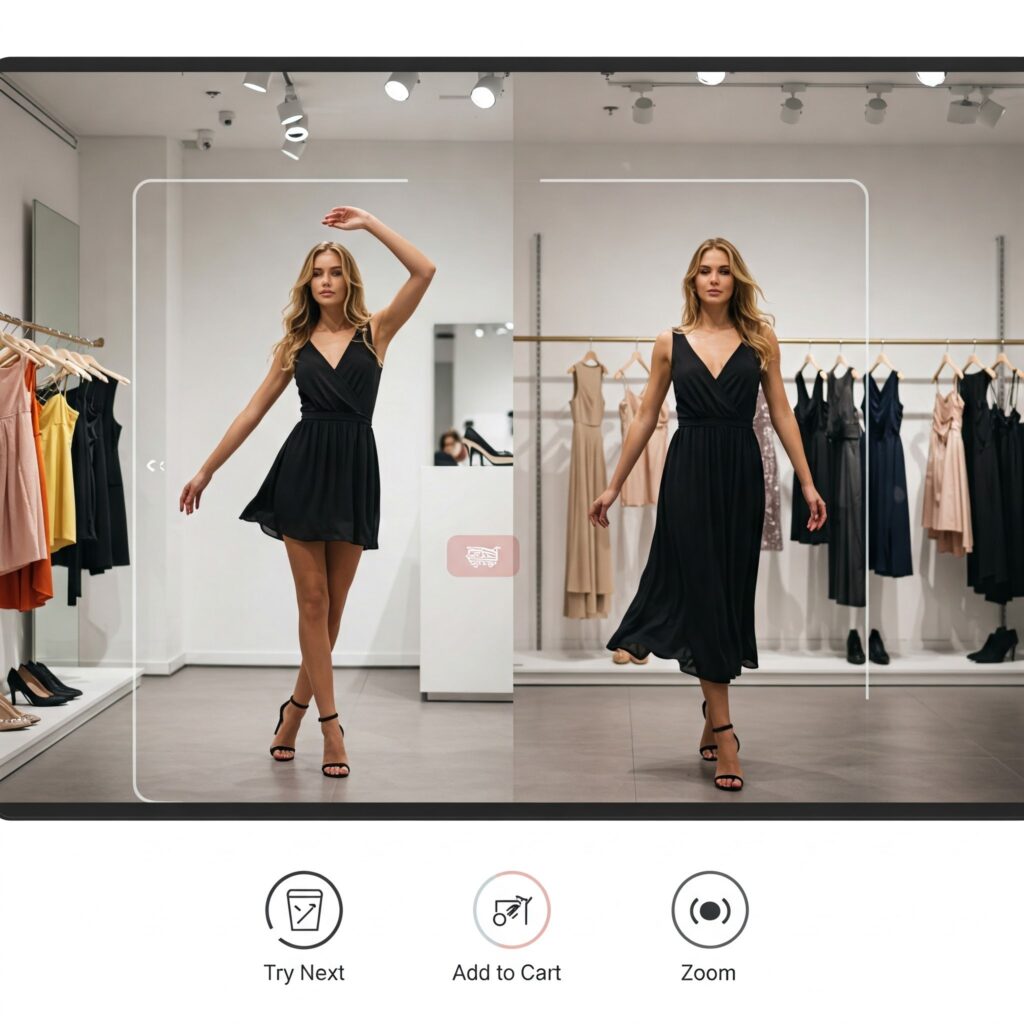

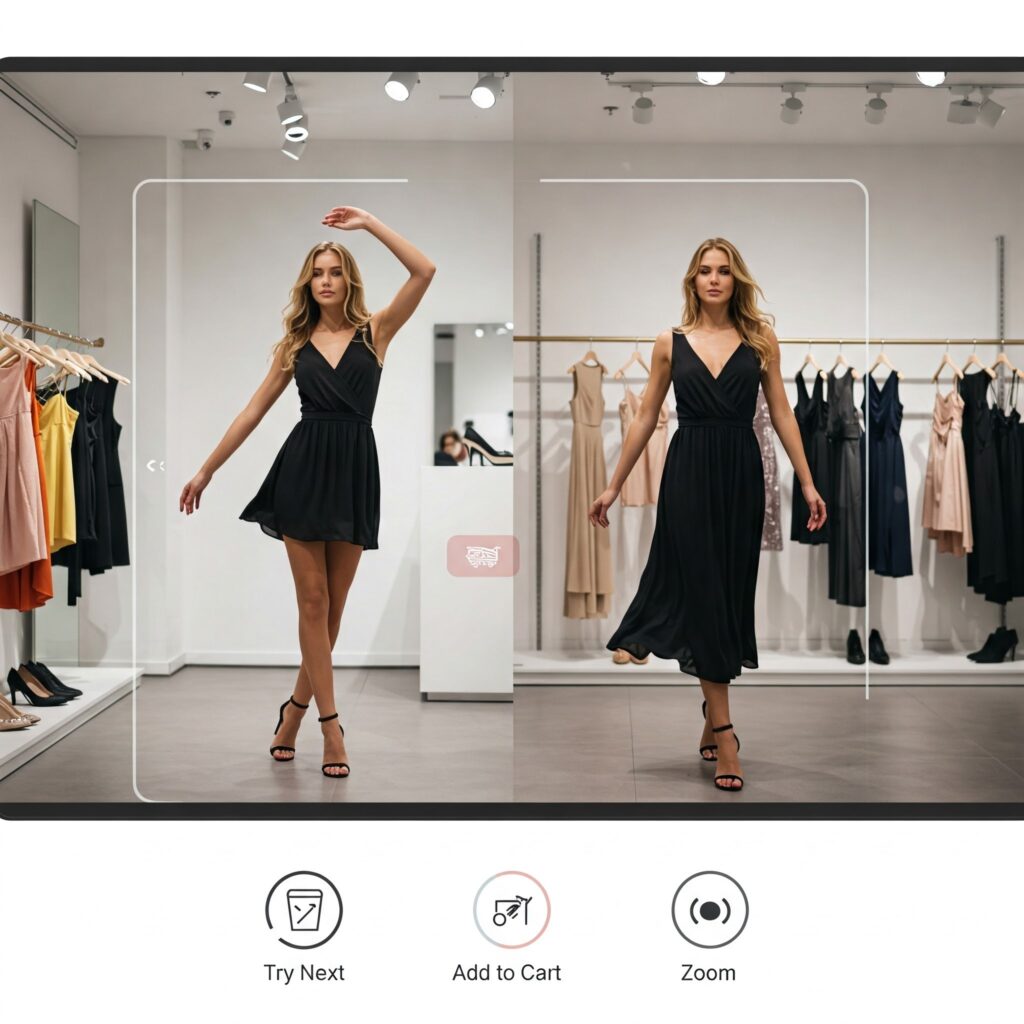

Achieving the Perfect Fit with Virtual Garment Fitting

Fit is a crucial element in the apparel industry. Ill-fitting clothing can lead to returns, lost sales, and dissatisfied customers. 3D Garment Design solves this problem by allowing designers to test how garments will fit on a virtual model before they even make them.

Here’s why this is important:

- Virtual garment fitting helps dressmakers see how different fabrics and cuts interact with the body.

- Adjustments to size and fit can be made easily, saving time and materials.

- Brands like Levi’s can now design jeans that fit better and require fewer changes during production.

By eliminating the need for multiple physical samples, this digital process ensures that each garment is a perfect fit from the start. This leads to better customer satisfaction and fewer returns.

Let’s dive into how 3d fashion design program gives fashion designers more creative freedom and flexibility.

Creative Freedom and Flexibility in Design

Every designer wants the freedom to explore their ideas without being held back by time or materials. With 3D Garment Design, they can experiment with new styles, fabrics, and techniques easily and without wasting resources.

Benefits include:

- Designers can explore different fabric combinations and design elements.

- The designing software offers flexibility to make quick changes to the design.

- It allows experts to create intricate details that would be difficult to visualize with traditional methods.

For example, brands like Gucci use 3D garment design software to push the boundaries of fashion. By seeing their ideas in 3D, they can make sure everything is perfect before moving forward with production.

With more creative control, let’s now look at how this development is helping make fashion more sustainable.

Sustainability: Reducing Waste with 3D Clothes Design

The fashion industry has long faced criticism for its environmental impact, particularly when it comes to waste. 3D Garment Design offers a way to reduce waste while still delivering quality clothing.

How it helps:

- Designers can visualize garments digitally before producing them, reducing the need for physical prototypes.

- It allows for better planning and forecasting, avoiding overproduction.

- Companies can cut down on fabric waste by making adjustments virtually.

Brands like Patagonia, known for their commitment to sustainability, use clothes designing programs to create accurate designs without using excessive materials. This makes their manufacturing process more eco-friendly and cost-effective.

Now that we’ve covered sustainability, let’s talk about how fashion design software improves collaboration between designers and manufacturers.

Improved Collaboration Between Designers and Manufacturers

Effective collaboration is crucial in the garment production process. 3D Garment Design enhances communication by providing both designers and manufacturers with a digital model of the garment they’re creating.

Why this is beneficial:

- Designers can share 3D models directly with manufacturers to communicate design intent.

- Manufacturers can provide feedback on production feasibility and suggest improvements.

- Adjustments can be made in real-time without the need for physical samples.

For example, H&M uses design clothes software to share 3D designs with their production teams, speeding up the process and ensuring that everyone is aligned.

Now, let’s explore how it is paving the way for the future of 3D fashion production.

Scalability and Automation: The Future of Fashion Production

As the demand for faster and more efficient production increases, fashion clothes design software is helping brands scale their operations without sacrificing quality.

Here’s how it works:

- It integrates well with automated manufacturing technologies like 3D printing and cutting machines.

- It allows for more efficient production processes, reducing labor costs and production time.

- Brands can quickly adapt to new trends and produce larger quantities of garments without compromising quality.

Nike and Under Armour have already embraced 3d clothing software to automate and scale their production, making it easier to meet growing consumer demand.

The benefits of clothes designing software in apparel manufacturing are clear. From improving efficiency and fit to enabling greater creativity and sustainability, this technology is changing the way clothes are made.

- It speeds up production cycles and reduces material waste.

- It ensures better fit and quality, leading to happier customers.

- It allows designers to experiment freely and push the boundaries of fashion.

- It makes manufacturing processes more sustainable and cost-effective.

For any fashion brand or manufacturer, adopting 3D Garment Design is not just a trend, it’s the future. Whether you’re a designer want to create new collections or a manufacturer wanting to improve production, this 3D clothing program offers endless possibilities.