Is your team struggling to keep product data aligned across departments? Do minor mistakes turn into major delays? These problems have become common and are increasing gradually. Every day, manufacturers face avoidable setbacks because their systems don’t talk to each other. That ends now.

In this guide, we’ll break down the key differences between PLM ERP systems, and more importantly, why integrating them is your smartest next move.

What Is PLM and ERP? Understanding the Building Blocks

Let’s start with the basics:

- PLM (Product Lifecycle Management) focuses on managing a product from its first concept through design, development, and service. It enables teams to collaborate on product data, drawings, and revisions across the product lifecycle.

- ERP (Enterprise Resource Planning) handles back-end business operations like finance, supply chain, inventory, and procurement. It ensures that resources are allocated efficiently to meet production and delivery goals.

So, while PLM powers innovation, ERP ensures execution.

This is your foundation for understanding how PLM ERP systems support different but equally vital business functions. Now let’s explore how they compare.

Quick Comparison: PLM vs ERP

Here’s a side-by-side look:

Feature | PLM | ERP |

Focus | Product design and development | Business operations and resource planning |

Users | Engineers, designers, R&D (Research & Development) | Finance, logistics, production teams |

Data Managed | CAD files, BOMs, specs | Inventory, costs, orders, scheduling |

Lifecycle Stage | Early-stage product lifecycle | Post-design execution and delivery |

This quick comparison clearly shows how both systems serve unique needs. Yet, when combined, their value multiplies.

Let’s explore why that matters.

Why PLM Integration With ERP Is Crucial in 2025 and Beyond?

Disconnected systems cause problems:

- Teams work from outdated or conflicting information, which leads to miscommunication and production errors.

- Launch timelines slip due to rework, slowing time-to-market and draining budgets.

- Departments lose trust in data accuracy, leading to poor collaboration and internal friction.

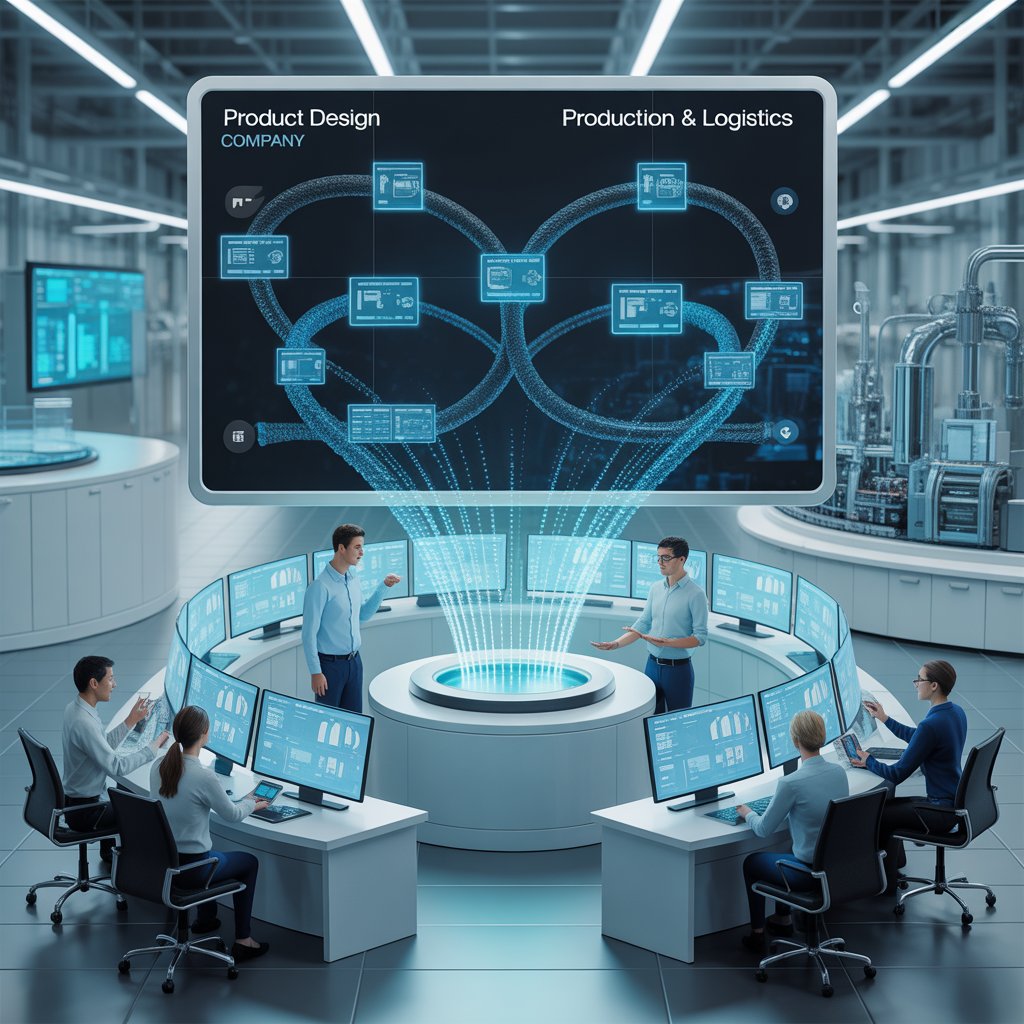

Integrating PLM ERP systems eliminates these pain points by syncing product design with business execution in real time.

Here’s what that gives you:

- One version of the truth across departments, ensuring all teams work from the most accurate, updated data.

- Quicker decisions based on accurate data, improving speed and precision in operations.

- Greater agility from concept to customer, enabling businesses to pivot rapidly in competitive markets.

Still wondering how that works behind the scenes? Let’s break it down.

How the Integration of PLM and ERP Actually Works

Here’s the workflow:

- Engineers use PLM to design the product and create the Bill of Materials (BOM), storing specs, part numbers, and configuration data.

- That data is transferred to ERP, which uses it to source materials, plan production, and schedule delivery with suppliers.

- When a change is made in PLM, it reflects instantly in ERP, eliminating lag and reducing costly mistakes.

No more duplicate entries. No more version mix-ups. These systems work in tandem to keep every stakeholder on the same page.

With such precision and control, it’s no wonder manufacturers are making this shift.

What Manufacturers Gain from PLM ERP Integration

If you build products, you need visibility, accuracy, and speed. Integration delivers exactly that.

Major benefits of syncing PLM ERP systems include:

- Faster product launches with fewer bottlenecks—accelerated timelines mean better market responsiveness.

- Reduced costs from less rework and better resource planning: errors are caught early before they become expensive.

- Stronger collaboration between design and production teams. They operate with better communication and fewer silos.

- Regulatory compliance through traceable product data ensures easier reporting and audits.

When product lifecycle management erp and execution tools work as one, your entire workflow transforms.

Still unsure? See what happens without integration.

What Happens When Systems Stay Disconnected

Without a connected ecosystem, businesses risk:

- Inconsistent product data that leads to errors—designs change, but updates don’t reach production in time.

- Increased manual work and approval delays—teams waste time entering and checking redundant data.

- Misalignment across product teams—engineering, manufacturing, and procurement operate in isolation.

Let’s say your engineering team updates the design but fails to communicate it properly. Your production team proceeds with the outdated version. That’s a costly mistake, and it’s avoidable.

So how do you make sure your teams stay aligned? By integrating your systems.

Real-World Use Case: From Chaos to Clarity

Picture this: A mid-sized manufacturer of smart appliances.

- R&D updates the motor specs in PLM, responding to a safety concern.

- ERP is unaware and continues using outdated data, resulting in incorrect parts being ordered.

- Hundreds of units are built incorrectly, requiring a full recall.

The result? A delayed launch and significant rework costs.

Now, with PLM ERP integration:

- The motor spec update syncs directly to ERP, automatically adjusting procurement requirements.

- Procurement and production pivot immediately, avoiding waste and preserving timelines.

- Product launches on time and error-free, saving the company both reputation and revenue.

That’s the power of connected systems.

And it’s not just about avoiding failure but about fueling innovation.

Strategic Upside of Integrating PLM System With ERP

Want to stay competitive? Then stay connected.

With smooth integration, your organization benefits from:

- Scalable growth as systems evolve—you can expand product lines without overloading your infrastructure.

- Global collaboration between distributed teams—international teams work from the same real-time data set.

- Accelerated R&D and iteration cycles—ideas move faster from prototype to production with fewer delays.

It also supports your sustainability initiatives by offering complete transparency across the lifecycle.

Let’s take it a step further and look at how this fuels digital transformation.

Digital Transformation Starts with PLM & ERP Integration

Smart factories. Real-time data. Predictive planning.

This integration powers:

- IoT-connected workflows that collect and analyze data directly from machines and sensors.

- AI-driven demand forecasting to optimize inventory and reduce overproduction.

- Automated supply chain decisions that respond instantly to shifting market or supply conditions.

With a digital thread that connects each phase, businesses move from reactive to proactive.

So how do you make the switch efficiently? Follow these proven strategies.

How to Begin Your PLM-ERP Integration Journey

Successful implementation begins with preparation:

- Identify gaps in your current workflow where teams experience delays or errors.

- Select tools that offer flexible integration and can scale with your operations.

- Align teams around clear integration goals, such as reducing time-to-market or improving traceability.

- Run pilot projects to fine-tune before scaling, using smaller teams to refine the process.

Working with integration partners ensures faster adoption and better ROI. Plm vs Erp isn’t a competition. It’s a relationship. And the winning strategy is plm erp integration.

Modern manufacturing demands more than tools; it demands alignment. If your systems aren’t talking, your teams aren’t either. But when PLM ERP solutions integrate, silos vanish, delays shrink, and your business grows faster, leaner, and stronger.